Search this site

Reduction of paper dust

At the beginning of diecut with a new die, you see quite little paper dust. After thousands of impressions, you may find it.

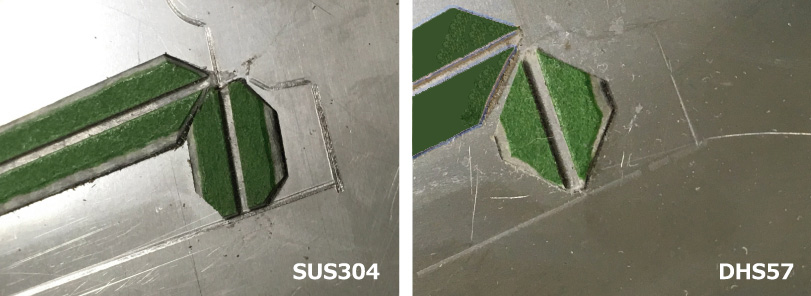

This would be because of the marks of cutting plate by cutting rule and worn or bent blade.

In this case, replacement of blade will clear this problem.

However, it is not the way to solve real cause.

Extension of blade replacement will also reduce paper dust.

Cutting plate 1.0mm DHS57

We would like to introduce our DAISO cutting plate 1.0mm DHS57.

Too soft or hard cutting plate does not work well.

Shore hardness Blade edge – 10 = Appropriate hardness of cutting plate

We recommend to select cutting plate hardness against blade edge hardness.

Usage of proper cutting plate enables to extend replacement cycle of cutting rule since the damage to edge blade becomes much less.

Reduction of damage to blade edge will decrease paper dust.

Type of cutting plate

| Material | HS | HV | Durability | Remark |

|---|---|---|---|---|

| DHS57 | 57 | 425 | ◎ | Excellent hardness and flatness |

| 1500SP | 64 | 480 | ◎ | Highly excellent hardness |

| DP2 | 52 | 378 | ○ | Good hardness and flatness, less quality comparing with DHS57 |

| SUS304 | 26 | 170 | △ | Standard hardness and flatness, easily cutting marked and occur paper dust |

| SUS430 | 29 | 162 | ✕ | Good cost, low hardness and flatness, easily cutting marked and rusty |

**Blade edge 70-80 HS