Search this site

Improve creasing line and reduce crack and torn-surface

Improve creasing line and reduce crack and torn-surface

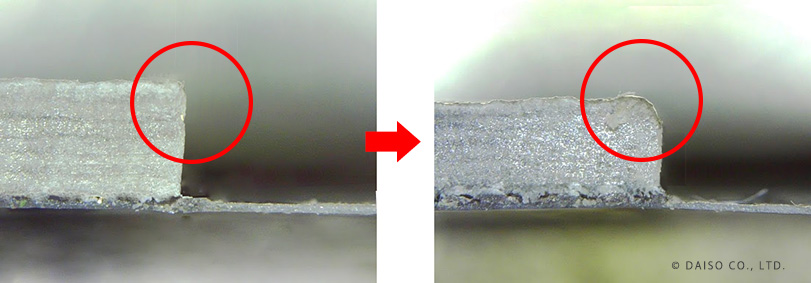

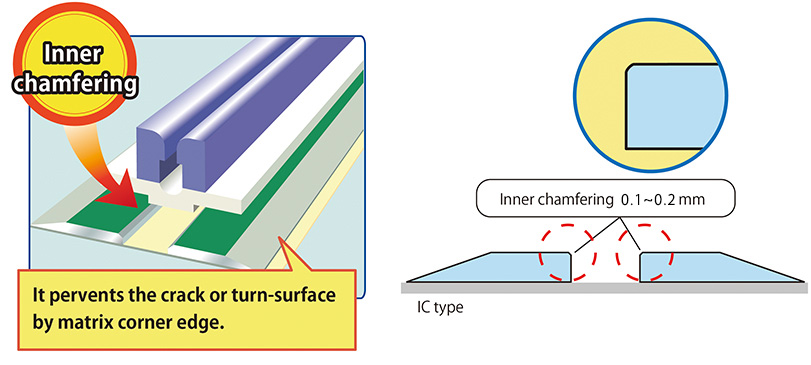

Trouble like crack and torn-surface might happen because creasing matrix makes too deep creasing, especially in the diecut of laminated sheets ( card board and corrugated board) or solid printing sheets.

Our matrix G-tape is arranged with tiny rounded processing at the corner edge basically.

In some cases of sheet materials or low moisture content, narrower slot width for better creasing could bring on crack and torn-surface because of corner edge.

This would be good solution to improve these problems.

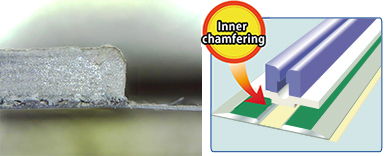

Inner chamfer processing G-tape IC type

G-tape is made from Vulcanized fiber which consists of cotton pulp and pulpwood as eco-friendly materials.

It is stronger and more durable material than other plastic materials and enables sharp creasing line.

Our matrix G-tape is arranged with tiny rounded processing at the corner edge basically.

We received some requests of bigger chamfer from customers.

Then we started to develop new types of creasing matrix to keep sharp creasing line and avoid crack and torn-surface.

We hope you can try new G-tape IC type (inner chamfer) as a solution.

We arranged inner edge chamfering 0.02-0.03mm to ensure stable creasing line from the beginning to the end.

Good solution for creasing trouble because of sheet materials or moisture content issue. Improve creasing line with our G-tape IC type.