Search this site

WHY G-Tape recommended?

Setting chart for G-Tape is basic idea of setting. However, dieboard condition, sheet quality, moisture etc. would be factors to make cracks.

Widen 0.1mm slot width to decrease folding torque. Decrease 0.1mm slot width to increase folding torque.

Thickness of matrix is not so affected if you change slightly. In that case, you can put patchup tape onto creasing rule.

For corrugated creasing, you can cut one side of matrix body to improve fish-tail problem.

Practical set up of G-Tape

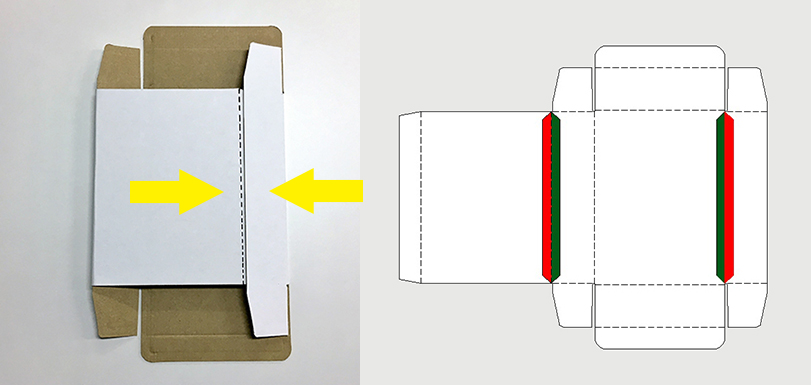

To adjust as yellow direction

Cut red side to make inside creasing stronger.

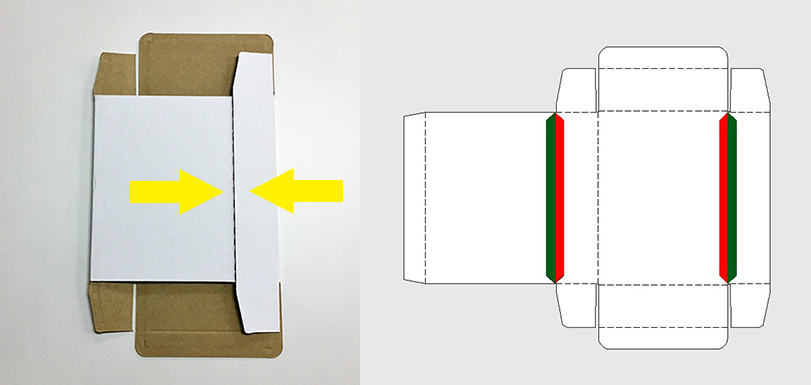

To adjust as yellow direction

Cut red side to make outside creasing stronger.

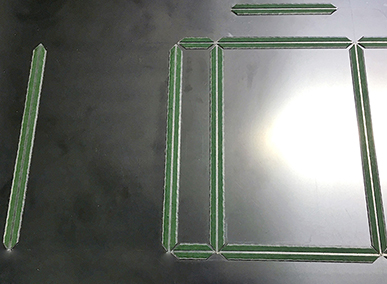

Hand cut, pertinax or G-Tape creasing matrix

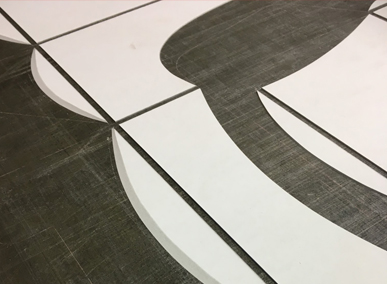

Hand cut

Hand cut was basic way of creasing 30 years ago. It is still common but needs skills and experience. Stable creasing is not easy for beginners. Flatbed has to stop to cut paper. Machine costs $ 200-300/h in average. This downtime is invisible cost indeed.

We provide Super-G glue, H-tack glue and carbon paper.

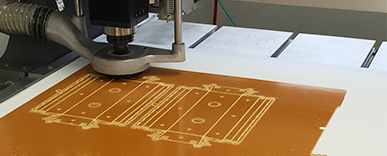

Pertinax

Pertinax is arranged by cutting machine. Advantage is easy to set up. After one press onto cutting plate, it will be ready with high quality creasing slot.

As disadvantage, large area of material is needed. The cost becomes high. You need CAD/CAM operators to handle. If you install machine, it is big investment.

We provide various pertinax counter plate, endmills and set-up tools.

G-Tape matrix

Creasing matrix is most popular way of creasing at the moment. Easy set-up for everyone.

Comparing with pertinax, if you like to make one creasing line stronger, you can change matrix size quickly. You just take off actual one then put new one.

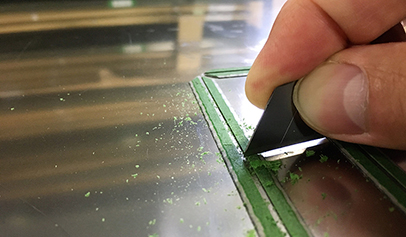

You need chamfer cut with utility knife for smooth running. Machine down time is cost as above. If you use VS-IV matrix cutter, you can cut with chamfering. Productivity becomes much higher.

You find the last short matrix from length 700mm. You may feel it is loss. Some customers keep last ones in small boxes each size to use for short creasing.

We joined Drupa 2016 and demonstrate Auto-matrix cutter. It is first cutter with chamfering in the world. Auto-matrix cutter with reel matrix improves productivity a lot and loss will be much less. Auto-matrix cutter will be released near the future.