Search this site

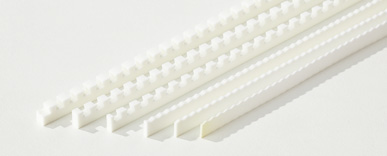

Slot ejector to keep knives straight

Effective Mizzokko slot rubber for stable diecut and less damage to blades

Effective Mizzokko slot rubber for stable diecut and less damage to blades

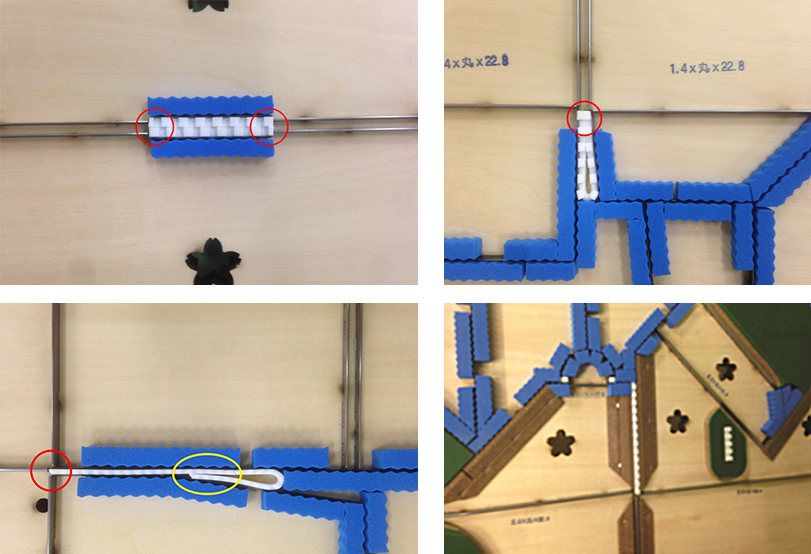

These positions are important to keep high speed press in diecut.

Degradation over time is difficult to avoid, however, the point is how to set rubber and stock condition.

Trick how to set Mizzokko rubber

The edge of rubber must be protrusion.

Congested area => More difficult to eject

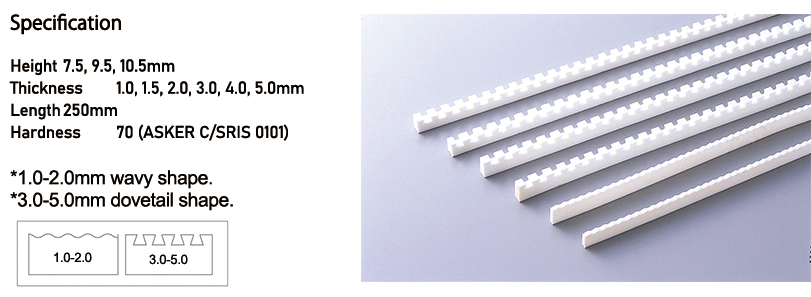

Mizzokko Specification

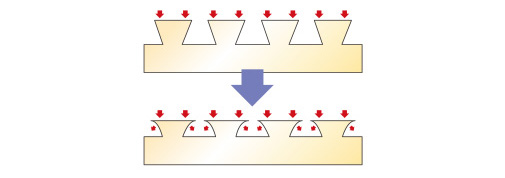

In diecut, Mizzokko is pressed as picture below.

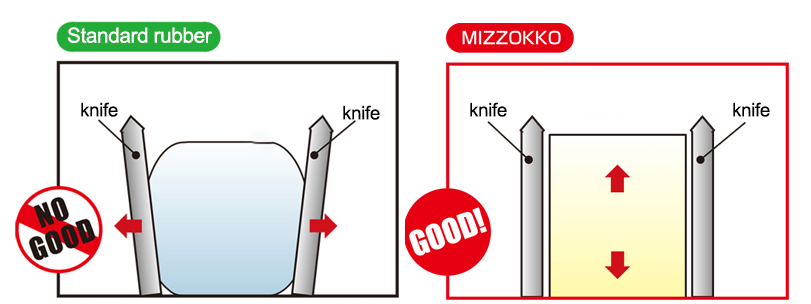

Much less pressure from Mizzokko to knives.

Special shape to keep knives straight

In diecut, Mizzokko is pressed as picture below.

Standard rubber expands to side.Mizzokko expands up and down.

Much less pressure from Mizzokko to knives.

How to keep stock

Avoid high humidity and exhaust gas from forklift trucks or other cars.

Well ventilated surroundings.

Natural rubber has high ejection, however, it is susceptible to air like hydrolysis.

Our Mizzokko rubber is made from Urethane which has excellent resilience, durability,

heat resistance and water resistance.

We developed and adopted this as an easy and stable product in your usage of dieboard.

As a conclusion

To avoid trouble and downtime leads to more productivity.

Especially in high speed machine and sheet cases, diemakers need to be committed such a small rubber.

We DAISO provide troubleless and productive dies with our original consumables based on our experience and discussion.