Search this site

- Die-cutting

- Eco-friendly creasing matrix

Eco-friendly creasing matrix

Contents

Environmental problems due to waste plastic

Global plastic production reached 380 million tons in 2015.

There are 2.5 billion tons of plastic still used as products, and 5.8 billion tons have been used.

Of the used plastic, 4.6 billion tons (79%) were disposed of in landfills, 700 million tons (12%) were incinerated, and 500 million tons (9%) were recycled.

Taking the recycled content into account, 4.9 billion tons of

waste plastic is finally generated. It is assumed that a lot of microplastics

are flowing into the sea due to the waste plastics in developing countries and

the lack of landfill management.

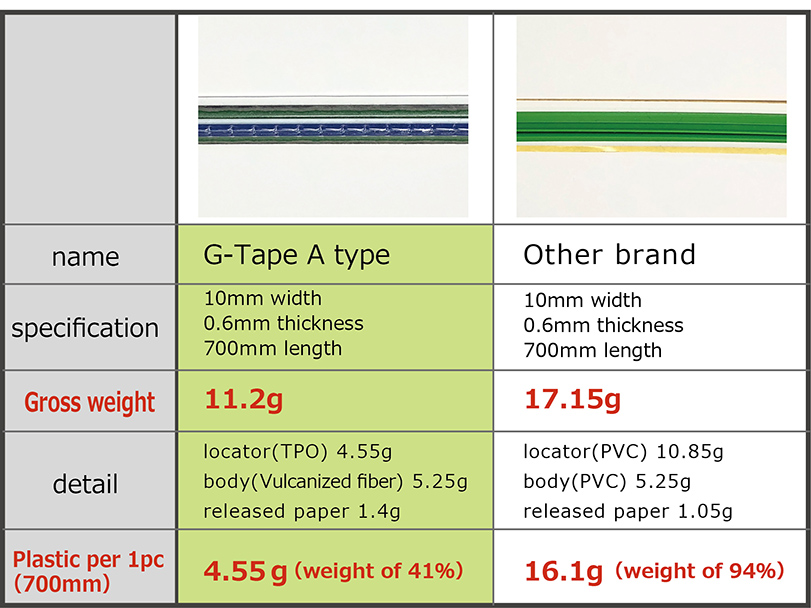

Difference between G-Tape and other brands

Our G-Tape has “vulcanized fiber” body since its release.

We are making products that take the global environment into consideration.

While cost reductions are required worldwide, 94% of other manufacturers are turning to plastics except released paper, while DAISO is reducing the amount of plastic used by utilizing the properties of olefin-based elastomers in the matrix locator.

G-Tape consists of eco-friendly materials that are environmentally friendly.

Eco-friendly fiber [deplasticization]

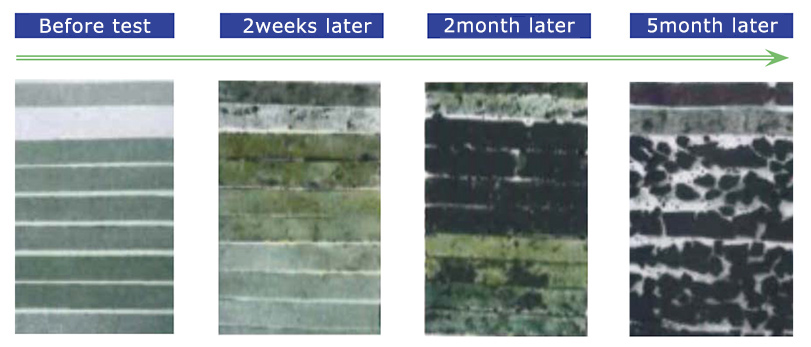

As a result of a biodegradation test in which microorganisms are buried in the soil and found to be mostly in the soil after 5 months.

“Biodegradation data”

The nature of microorganisms in the soil and water to be naturally decomposed into inorganic substances.

Biodegradable process

“Vulcanized fiber” is a material made from cotton

pulp and wood pulp. In addition to rigidity, toughness, impact resistance and

abrasion resistance, it has various characteristics such as insulation,

non-charging, arc resistance and tracking resistance.

【Characteristic】

■ Rigidity, toughness, impact resistance, wear resistance

■ Insulation, non-charging, arc resistance, tracking resistance

■ Light weight, oil resistance, solvent resistance, durability

■ Non-thermal melting, non-condensing, moisture absorption and desorption

■ Biodegradability, antistatic

We joined OSAKA Zero Carbon Foundation to contribute to the construction of a decarbonized (zero carbon) society through public-private partnerships.

It sustains environmental constraints on a global scale in harmony with the environment by carrying out a wide range of activities that contribute to SDGs and decarbonization in cooperation with members, Osaka Prefecture, and local governments.

The purpose is to contribute to the realization of a possible economic society.

We keep reducing plastic waste and improve the recycling system in our creasing matrix and the other diecut consumables production.

Sustainable and Responsible for the future